Mining Project: Methods to Mitigate Fire and Explosion Hazards of Lithium-ion Batteries

| Principal Investigator |

|

|---|---|

| Start Date | 10/1/2022 |

| Objective |

Battery electric vehicle development for underground mining continues at a rapid pace. From a diesel emissions reduction perspective, the benefits of employing battery electric vehicles (BEVs) are arguably greater for underground mining than any other industry. However, lithium-ion batteries are made from flammable materials and have the potential to introduce fire and explosion hazards. Several mishaps have already occurred in underground mines in the early stages of BEV deployment, emphasizing the ongoing need to mitigate fire and explosion hazards. For gassy mine applications, the mining industry has unresolved questions about the potential for pressurized explosions within explosion-proof enclosures containing lithium-ion batteries. |

| Topic Areas |

Research Summary

Approach

Battery thermal runaway pressure measurements will be used to help to answer questions about the potential for pressurized explosions within explosion-proof enclosures. Pressure measurements will follow methods developed at the Pittsburgh Mining Research Division and described in Dubaniewicz et al. [2022]. A thermal stability study will determine at which temperature battery cells provided by a collaborating equipment manufacturer can initiate exothermic reactions. Heat-Wait-Seek methods and an accelerating rate calorimeter (ARC) will be used for this purpose. This pilot project will also investigate methods to analyze hydrogen fluoride and other gas emissions from battery fires for further study. Finally, this project will identify gaps in equipment requirements and standards for further study related to environmental conditions such as impact and vibration. Measurements or estimates of underground mining equipment impacts or vibrations will be sought.

Milestones and Accomplishments

| Description | Audience | Year |

|---|---|---|

| Thermal runaway-generated pressure and enclosure volume dependency findings will be used to revise an international safety standard for explosion protected equipment. | Explosion-protected equipment manufacturers | 2023 |

Planned Impacts and Outcomes

The research will inform industry-wide efforts to mitigate large-scale BEV fires and explosions. Thermal runaway experiments will be designed to determine if explosion-proof enclosure assessment criteria should be enhanced to mitigate excessive over-pressures and temperatures. A thermal stability study will determine at which temperature exothermic reactions can be initiated in battery cells used for underground BEVs, with these findings being useful for battery thermal management. The investigation of gas analysis methods will inform longer-term research to mitigate health and safety risks of gasses released by battery fires. A comprehensive literature review on Mine Safety and Health Administration (MSHA) requirements and standards used by other industries will identify potential knowledge gaps of impacts, vibrations, and other environmental conditions that underground BEVs are subjected to.

Outputs

Dubaniewicz TH, Barone TL, Brown CB, Thomas RA [2022]. Comparison of thermal runaway pressures within sealed enclosures for nickel manganese cobalt and iron phosphate cathode lithium-ion cells. J Loss Prev Pro Ind 76:104739.

Rayyan N, Brown C, Dubaniewicz T H [2023]. Thermal runaway of LTO and NCA lithium-ion batteries in a sealed enclosure containing methane. SME Annual Meeting Preprint 23-043, Denver CO, March 1.

Tang W, Yuan L, Thomas R, Soles J [2023]. Comparison of fire suppression techniques on lithium-ion battery pack fires. SME Annual Meeting Preprint 23-006, Denver, CO, March 1.

Supporting Visuals

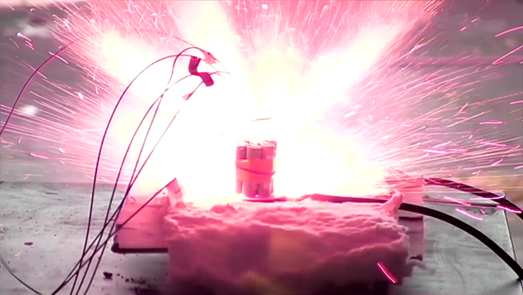

Several mishaps have occurred in underground mines in the early stages of BEV deployment. Photograph taken by a worker trapped inby a BEV fire.

Experimental characterization of lithium-ion battery thermal runaway phenomena to develop recommendations for mitigating fire and explosion hazards.

- Determining the Root Causes of Flame Cutting and Welding Fires in Underground U.S. Coal Mines

- Evaluation of the Bagged Stone Dust Barrier Effectiveness in a Bord and Pillar Mine

- Explosion Temperatures and Pressures of Metals and Other Elemental Dust Clouds

- Initial Study of Buried Communication Cable for Underground Mines

- Mitigating Fire and Explosion Hazards of Lithium-ion Batteries

- Rapid (Grab) Sampling During Full-scale Explosions - Microscopic and Analytical Evaluation

- Reducing the Fire and Explosion Hazards of Flame-Cutting and Welding in Underground Coal Mines

- Remotely Installed Mine Seals for Mine Fire Control

- A Review of Recent Accidents Involving Explosives Transport

- The Role of ASTM E27 Methods in Hazard Assessment: Part II - Flammability and Ignitability

- U.S. Bureau of Mines Technology Applicable to Disaster Response, Urban Search And Rescue